Recently we went on a trip to Switzerland for a Blancpain Manufacture visit at both their production sites.

Precision is key at Blancpain Manufacture

Beginning at the Les Sentier workshops we start of at the beginning of the watches. Having a strict no-photography policy in this part of the production facility we’ll try and explain what’s happening here. In a storage room several kinds of raw material are in stock. Various rolls of metal strips to bigger raw pieces of metal are waiting for the production process. Here we find several machines that produce base parts for the movements like base plates. Apart from that there are also complicated parts which are pressed from raw material in several steps.

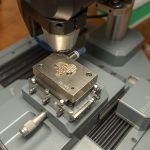

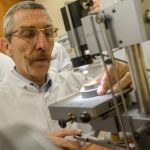

Base plates are stamped from strips of metal and get their first alignment holes drilled. Allowing them to be machined with great accuracy needed at all the following steps of the production process. While going through several steps the base plates are machined until they are ready for finishing and finally the assembly into an actual movement. During the entire production progress precision is key. For this reason all parts are heated for longer periods and thoroughly cleaned several times for an optimum product in the end. Besides that they check the each part multiple times by measuring several dimensions during the production process.

Moving on through the facility we learn that all tools that are used for the production of parts are actually made in-house. We even visit a small production work shop were small tools are handcrafted from raw metal. All the watch makers actually use screwdrivers made in this workshop. This includes everybody working at a service center anywhere in the world. Moving on we stop over at a storage room where all the used stamping tools are stored which allows the Blancpain manufacture to re-produce pretty much any parts that has ever been made.

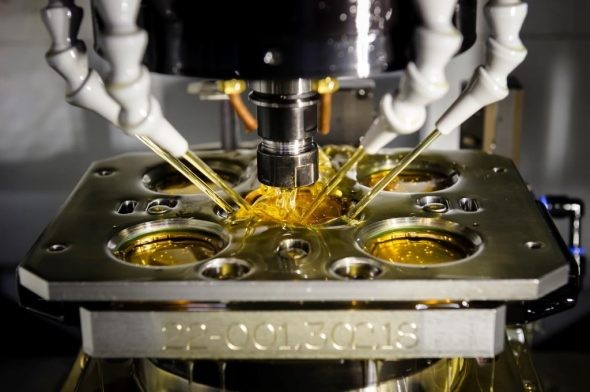

Machining of base parts

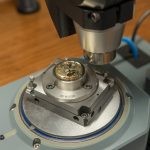

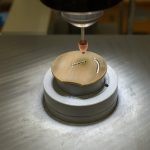

Next stop is in the machining area where several milling machines are working on various parts. Here we see how base plates being loaded for milling automatically and being machined for the several watches. Base plates are being machined in several steps and small parts are cut out. Interesting to see is how the rotors are made. Starting off with a small disk of gold, material is removed until the final rotor is ready when most of all material is discarded and only little is left. Yet all the gold that was discarded during the process is recovered and re-used. Same goes for all the non-precious metal. Once again it is explained how important precision is and that regularly parts are being tested for accuracy. Several charts showing up to date analysis from which we learn that everything has been made within the small margins allowed.

The Farm at Le Brassus

Here we change into Blancpain manufacture dust coats and begin our tour of the workshops. First stop is meeting watch makers who are hand finishing several components manufactured at Les Sentier. Watch makers polish all the tiny watch parts by hand using small wooden tools and one piece at the time. At another station the “Geneva stripes” or “Côtes de Genève” are applied as well as perlage. We can try applying the perlage ourselves by hand. We quickly realise how hard this actually is, especially for the untrained hand.

Next level watch making

Continuing our tour of ‘the farm’ we visit the next department of high watch making at the tourbillon workshop. Here we can see how watch makers are working on various high end watches with a tourbillon, carrousel or even both. Explanation about the tourbillon and Carrousel here. Each of these high end watches are assembled by the one and the same watch maker. With some ready assembled movements placed under a microscope the high-end level of finishing can be seen as well as explained how several parts inside the movement function.

For the next level in watch making we visit the minute repeater workshop. As the name already indicates this is where the most complicated watches are assembled and tested. Again each movement is assembled by oen watch maker who is responsible for the entire process. Here we learn how the movement of a minute repeater works and what it takes to build such a complication. Interesting to learn is that the gongs are also modified by hand for the optimum sound according to the wacht maker. Small amounts of material is taken away or added to achieve this.

Customising your personal watch

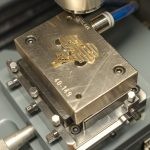

Besides the ‘standard’ watches this is also the place where the custom watches are assembled. As you probably know Blancpain also makes erotic scenes on request. Being openminded enough to add these personalised and moving erotic scenes, each design has to be approved for production. As customisation is part of their work they are happy to personalise your watch for you. Wether it is just a custom rotor, dial or movement decoration, Blancpain is happy to create your dream watch as we see in one of the engraving workshops. Here they are working on special hand engraved dials and movements. We are shown some sample images delivered by customers which are translated into some stunning watches.

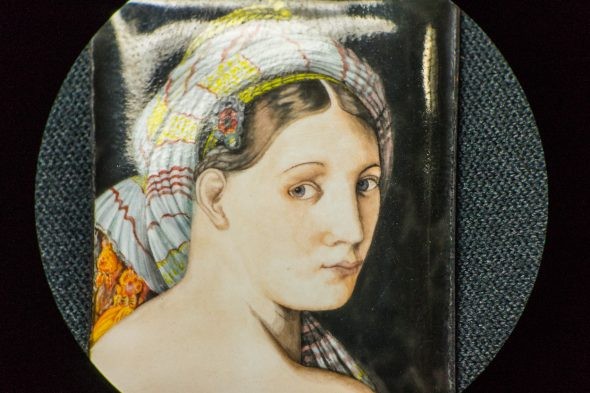

Finally we visit the workshop for custom dials. Here enamel dials are being painted with the utmost precision and details. Complete paintings are transferred onto watch dials which measure just a few centimeters. Having a look through the microscope you will find it hard to believe this is actually possible.

After this last workshop we return the meeting room where we say goodbye to Blancpain and head back home. We’ve enjoyed the visit and have learned a lot about the production process and it wat impressive to see the amount of time and effort that is being put into precision and details of the entire production process. Big thank you to Blancpain and all involved who made this trip possible and such a great experience.

Superb !!

Many thanks to Blancpain for sharing their secrets and savoir faire which are whole part of our watches.